Conductor :

ACS-Aluminum Clad Steel Wire (Alumoweld)

Certificate: ISO 9001

Supply Ability: 5000km/Month

Packaging Details: Wood Drum, Wood-metal Drum or Metal Drum.

Port: Qingdao / Tianjin/ Ningbo / Shanghai

Send message

Send message

ht@htcable.cn

ht@htcable.cn

.jpg)

.jpg)

■Feature

- Corrosion resistant in industrial, semi-industrial and marine environments

- Superior to aluminized steel

- Light weight

- Same tensile strength as extra high strength steel but weighs 15 percent less

- Excellent conductivity–much more conductive than galvanized steel and aluminum

■Application

Aluminum-Clad Steel Wire Strand Conductor is a bimetallic wire which steel wire is covered by Aluminum evenly with advantages of good. electric conductivity, anti corrosion, good high frequency transmission and high intensity. Aluminum-coated steel core aluminum stranded wire is a stranded wire which strands Aluminum-Clad Steel wire as reinforce core with aluminum wire.

Compared with common Aluminum conductor steel reinforced, Aluminum-Clad Steel Wire Strand Conductor has the following advantages of 5% weight reducing, 2-3% load increase, 4-6%electric loss reduction, longer life and no extra cost. It is widely used for electric transmission line conductors, especially for coastal areas, salt alkali beach, grade 3 or grade 4 polluted industrial zone and the place with requirement of enlarged Aluminum steel cross-section ratio.

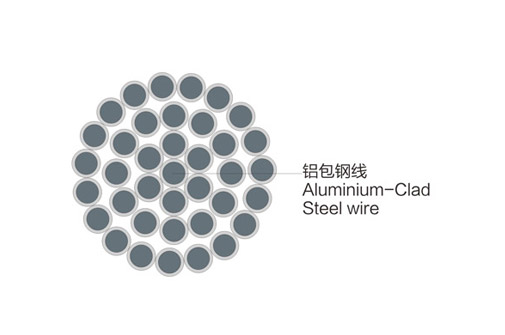

■Structure

Aluminum-Clad Steel wires are concentrically stranded and wrapped helically around a central wire. Each successive layer has six wires more than the previous underlying layer. Outer layer is right or left hand lay and reversed in successive layers.

■Standard

Products can be manufactures according to IEC standard,ASTM standard,BS standard,DIN and other standard and customizable cable.

■Download

| Code Number | Area | No.of wires | Diameter | Weight | Rated Strengh | Max.D.C. Resistance at 20℃ | |

| Wire | Cond.

|

||||||

| mm2 | mm | mm | kg/km | kN |

Ω/km |

||

| 3 N0 5Awg.

|

50.32 | 3 | 4.62 | 9.96 | 334.1 | 54.42 | 1.699 |

| 3 No 6Awg.

|

39 | 3 | 4.11 | 8.87 | 265.0 | 45.74 | 2.142 |

| 3 N0 7Awg.

|

31.65 | 3 | 3.67 | 7.9 | 210.1 | 38.36 | 2.701 |

| 3 No 8Awg.

|

25.1 | 3 | 3.26 | 7.03 | 166.7 | 32.06 | 3.406 |

| 3 N0 9Awg.

|

19.9 | 3 | 2.91 | 6.26 | 132.2 | 25.43 | 4.294 |

| 3 N0 10Awg.

|

15.78 | 3 | 2.59 | 5.58 | 104.8 | 20.16 | 5.415 |

| 7 N0 5Awg.

|

117.4 | 7 | 4.62 | 13.9 | 781.l | 120.27 | 0.7426 |

| 7 N0 6Awg.

|

93.1 | 7 | 4.11 | 12.4 | 619.5 | 101.14 | 0.9198 |

| 7 N0 7Awg.

|

73.87 | 7 | 3.67 | 11 | 491.1 | 84.81 | 1.160O |

| 7 No 8Awg.

|

58.56 | 7 | 3.26 | 9.78 | 389.6 | 70.88 | 1.463 |

| 7 N0 9Awg.

|

46.44 | 7 | 2.91 | 8.71 | 308.9 | 56.2 | 1.844 |

| 7 N0 10Awg.

|

36.83 | 7 | 2.59 | 7.76 | 245.1 | 44.58 | 2.325 |

| 7 No l1Awg.

|

29.21 | 7 | 2.3 | 6.91 | 194.4 | 35.35 | 2.932 |

| 7 N0 12Awg.

|

23.16 | 7 | 2.05 | 6.16 | 154.2 | 28.03 | 3.697 |

| 19 No 5Awg.

|

318.7 | 19 | 4.62 | 23.1 | 2129.0 | 326.39 | 0.2698 |

| 19 N0 6Awg.

|

252.7 | 19 | 4.11 | 20.6 | 1688.0 | 274.55 | 0.3402 |

| 19 N0 7Awg.

|

200.4 | 19 | 3.67 | 18.3 | 1339.0 | 230.18 | 0.429 |

| 1g N0 8Awg.

|

158.9 | 19 | 3.26 | 16.3 | 1062.0 | 192.41 | 0.5409 |

| 19 N0 9Awg.

|

126.1 | 19 | 2.91 | 14.5 | 842.0 | 152.58 | 0.6821 |

| 19 N0 10Awg.

|

99.96 | 19 | 2.59 | 12.9 | 667.7 | 121.00 | 0.8601 |

| 37 N0 5Awg.

|

620.6 | 37 | 4.62 | 32.3 | 4170.0 | 635.43 | 0.1394 |

| 37 Na 6Awg.

|

492.2 | 37 | 4.11 | 28.8 | 3307.0 | 534.85 | 0.1757 |

| 37 N0 7Awg.

|

390.3 | 37 | 3.67 | 25.7 | 2623.0 | 448.09 | 0.2216 |

| 37 No aAwg.

|

309.5 | 37 | 3.26 | 22.9 | 2080.0 | 374.67 | 0.2794 |

| 37 N0 9Awg.

|

245.5 | 37 | 2.91 | 20.3 | 1649.0 | 279.11 | 0.3523 |

| 37 N0 10Awg.

|

194.7 | 37 | 2.59 | 17.9 | 1308.0 | 235.61 | 0.4443 |

Related products

Email: 623227522@qq.com

Email: 623227522@qq.com

Tel: +86-18637911633

Tel: +86-18637911633

Fax: 0379-67522688

Fax: 0379-67522688

Your position :

Your position :