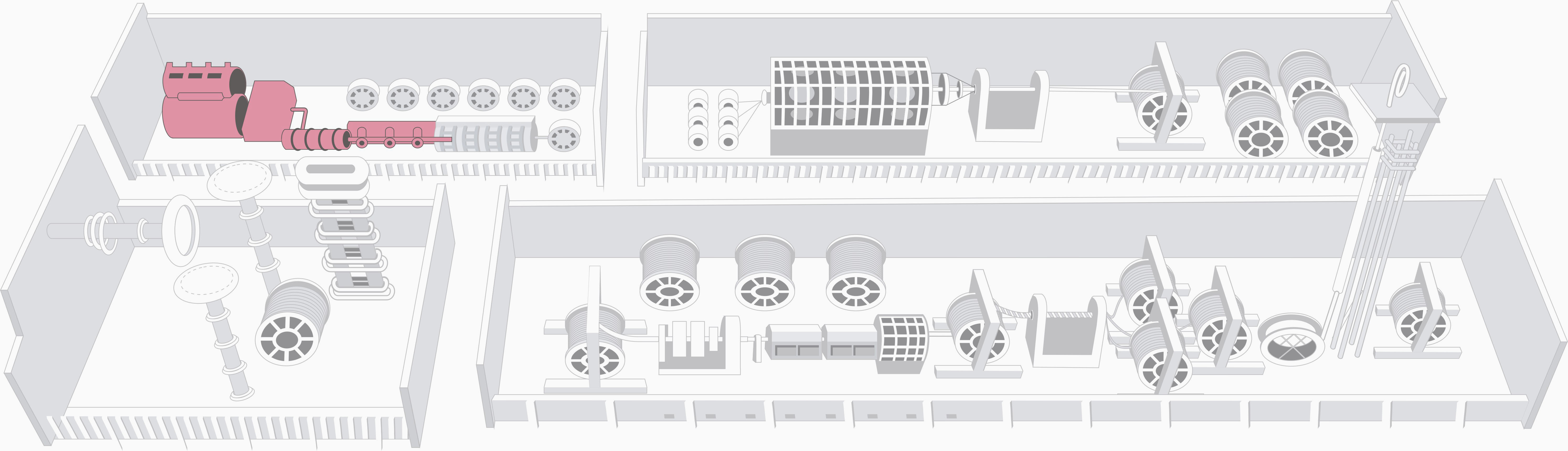

Manufacturing Process :

Processing Process

- 01

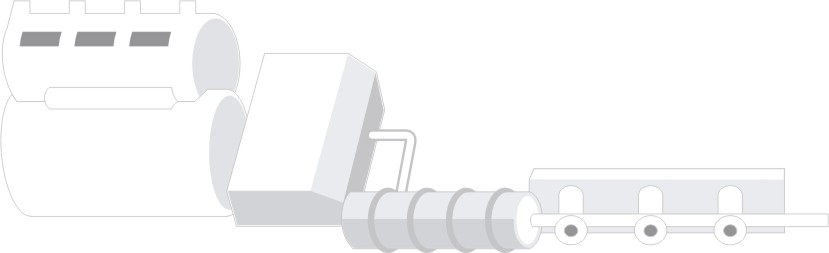

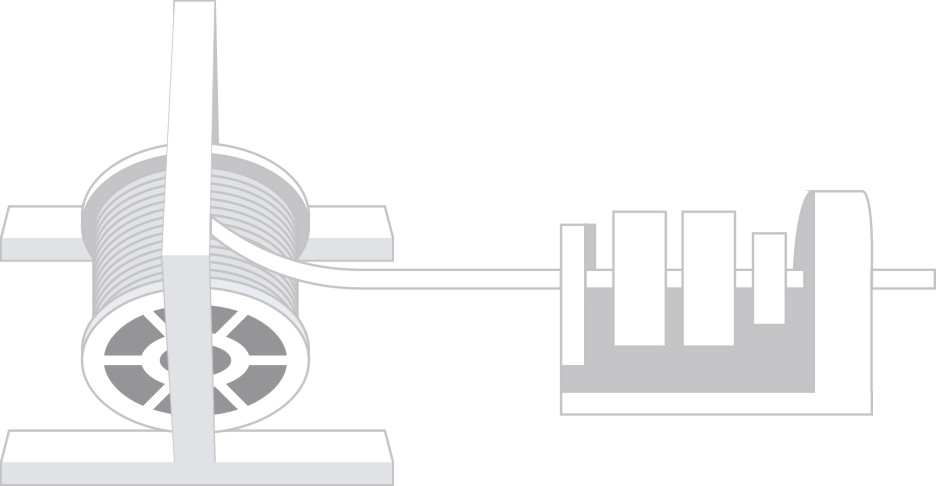

CCDR(Continue Casting Direct Rolling

Put the Aluminum ingot into the melting furnace, moulding it into Aluminum rod or Aluminum alloy rod of diameter 8-9.5mm after melt.

- 02

Wire drawing

Draw the electric round aluminum rod into wire of diameter 0.15-5mm with high-speed drawing equipment.

- 03

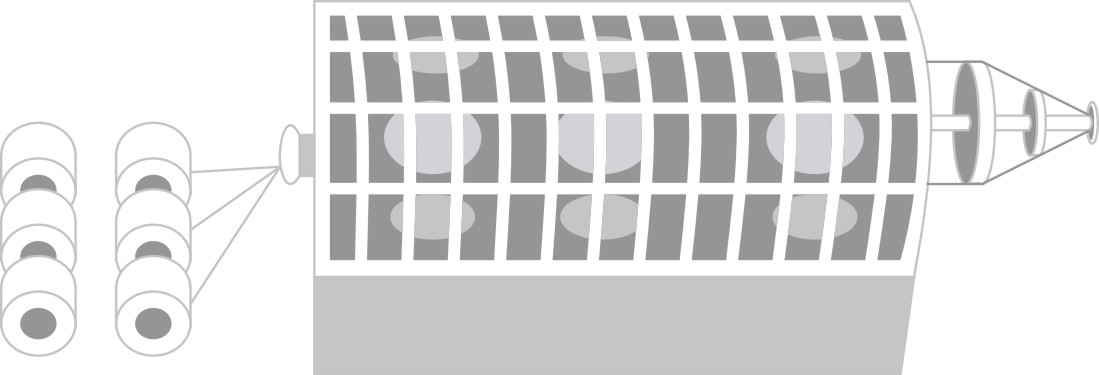

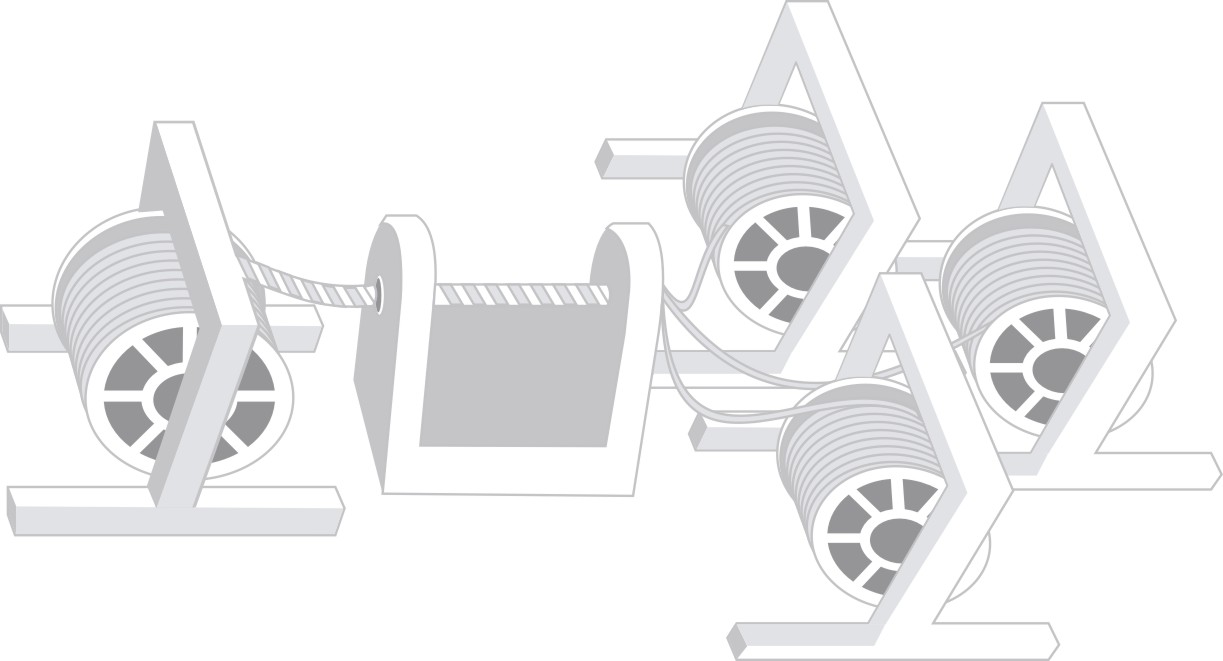

Stranding

Strand one or more wire layers surrounding the concentric wire into conductor.

- 04

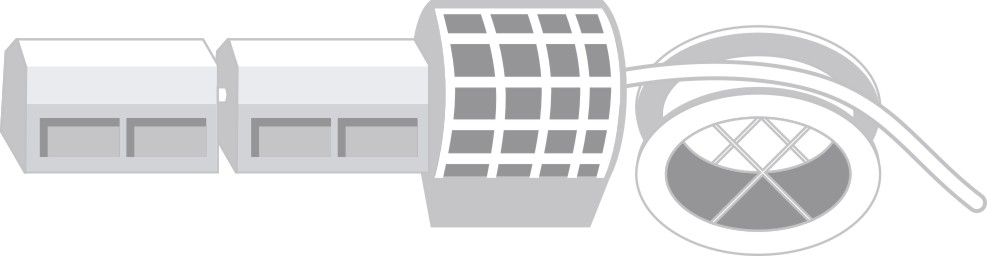

Insulation

Extrude the conductor with the XLPE raw material surrounding it, material cross link under high- temperature and high-pressure, then cooled to be insulation.

- 05

Cabling

The process to bunch several insulated conductors into one.

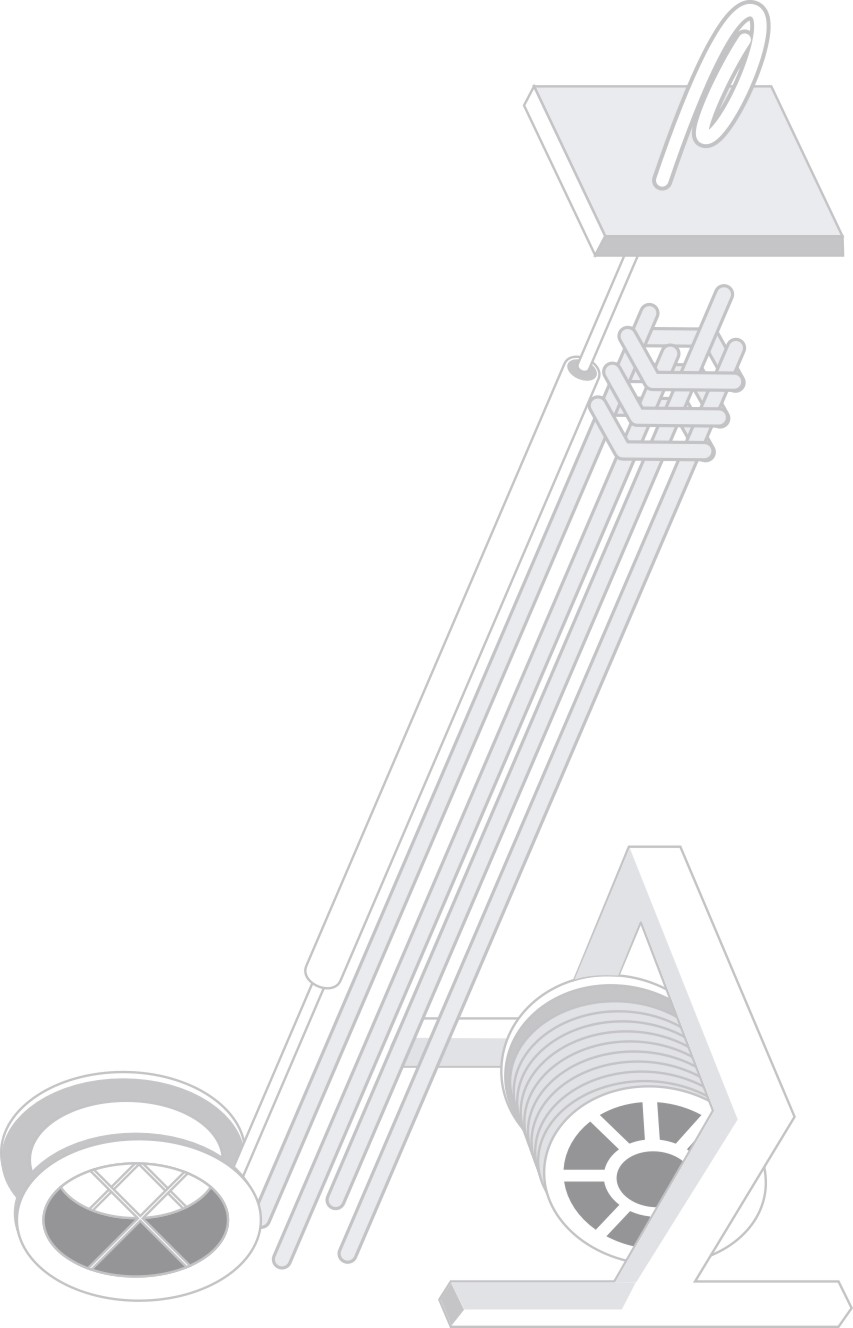

- 06

Metal armoring

In order to protect the insulated conductor, surround the insulated conductor with magnetic or non magnetic metal material, like steel wire or aluminum wire.

- 07

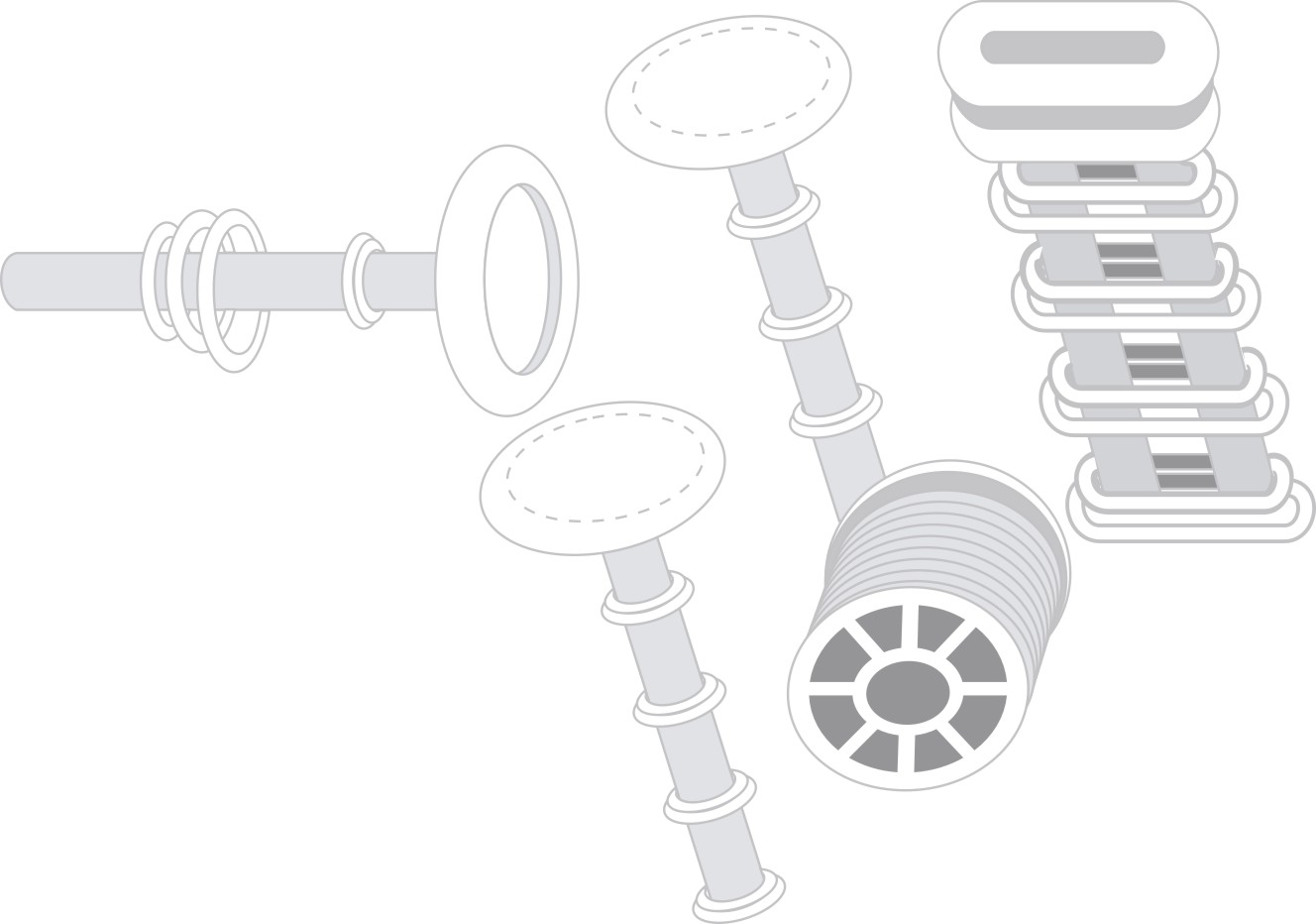

Sheath

Extrude the cable after surround the semi-finished armored insulated conductors with melting PVC or PE.

- 08

Test

The power cable plays an important role in power transmission lines, can be used only after strict testing.

Email: 623227522@qq.com

Email: 623227522@qq.com

Tel: +86-18637911633

Tel: +86-18637911633

Fax: 0379-67522688

Fax: 0379-67522688

Your position :

Your position :